LUMBERMENOnline.com’s Latest Industry News & Articles

Submit your company’s latest news or articleOCTOBER 2023 - Capturing the robust interest of battery-powered outdoor equipment and electric vehicles (EV), Wood-Mizer, a globally renowned leader in the sawmill industry, introduces the industry’s first battery-powered portable sawmill. The lithium-ion battery-powered sawmill provides sawmill owners an alternative power choice which is environmentally friendly and delivers consistent, reliable, and high-quality sawing performance. The battery power option is now available on the popular Wood-Mizer LT15WIDE portable sawmill that enables woodworking hobbyists and forestry professionals to safely and efficiently saw logs into lumber.

Industry-First Battery-Powered Portable Sawmill

With feedback from several large community-driven and passionate sawmilling groups, Wood-Mizer’s strong commitment to answer their requests and interests led to developing a battery option on the popular LT15WIDE portable sawmill. The Wood-Mizer LT15WIDE sawmill currently offers a wide range of gas, diesel and electric power options with battery-power being the latest addition. 100% of the sawmill’s functions are powered by lithium-ion batteries which are the leading-edge technology in the automotive and outdoor power equipment industries. In addition to reducing carbon emissions, lithium-ion batteries are convenient, lightweight, easy to store, safe, and rechargeable.

“Wood-Mizer strives to provide the sawing industry with the most choices to accommodate various applications and preferences,” says John Smith, Wood-Mizer CEO. “We take pride in closely listening to our customers and the industry and willingly invest in research and development in new products. Most importantly, we are committed to pushing the industry to the next level.”

Features of the Wood-Mizer LT15WIDE Battery-Powered Portable Sawmill

The LT15WIDE battery-powered portable sawmill frees sawyers from relying on fluctuating fuel prices, reduces costs and time associated with fuel engine maintenance, and provides a more comfortable operation with reduced noise and odor. Offering the same optional trailer package and 36” log diameter sawing capacity as the LT15WIDE portable sawmill, the battery version comes with additional technological enhancements including:

• Patent-pending “Smart Feed” technology continuously monitors the amperage while sawing and will speed up or slow down the feed rate to optimize sawing performance.

• Powered saw head up/down raises and lowers the sawmill blade quickly and accurately for the next cut with servo driven power.

• On-board computer includes 3 independent libraries within the setworks that allow the sawyer to hold up to 13 board thicknesses within each library for creating custom cutting programs.

• Advanced saw head return includes bump return or stack return options depending on the sawyer’s needs. The “bump return” brings the head back for off bearing an individual board while production sawyers will opt for the “stack return” which returns the head and positions the blade for the next cut while the sawn boards remain in place.

Tested and Proven Lithium-Ion Battery Technology

Rigorous field testing in locations throughout the world has proven the LT15WIDE battery-powered portable sawmill can saw constantly and consistently for up to eight hours on six batteries depending on wood species, sawing conditions, and amount of time spent in the cut. As the State of Charge (SoC) of the batteries reduced, sawyers reported that the sawmill continued to perform at peak levels throughout the eight hours without losing power or performance. In addition, the patent-pending “Smart Feed” technology ensures the sawmill automatically adjusts to wood species, log size, and blade conditions to provide optimal sawing feed rates and overall performance.

The lithium-ion batteries for the sawmill are derived from proven technology established in the automotive industry and governed by multiple safety standards. The batteries have passed internationally recognized design and testing requirements that cover compliance with vibration, thermal shock, drop test, mechanical shock, external short circuit, overcharge protection, overdischarge protection, over temperature protection and altitude.

The base model LT15WIDE battery-powered portable sawmill comes standard with four rechargeable lithium-ion batteries but can run on up to five or six batteries. Each battery weighs approximately 20pounds, includes a 1.4 kWh capacity, and is covered by a 5-year warranty. The included six-battery charging base allows sawyers to charge all four batteries in under four hours, five batteries in under five hours, six batteries in under six hours, and is compatible with a standard single-phase (15 amp) 110 AC wall outlet connection.

Market Availability and Pre-Orders

European sawyers who are interested in using an alternative power source for sawmilling can preorder Wood-Mizer’s LT15WIDE battery-powered portable sawmill for an estimated end of year 2023 delivery. For those in the United States, pre-orders are being taken with an anticipated Spring 2024 delivery. Customers in the United States can also take advantage of new tax credits which became available in January 2023 with the Inflation Reduction Act (IRA). The IRA tax credit is available for US customers who purchase battery operated mobile machinery that operates at 7 KwH which is equivalent to a minimum of 5 batteries. For more information, pricing, and availability, visit woodmizer.com or contact your local Wood-Mizer representative.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a world-leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. Serving more than 100,000 customers throughout the world From Forest to Final Form®, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, sawmill blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world. Visit woodmizer.com for more information.

Wood-Mizer announces winners of their 2023 My Wood-Mizer Project Contest - a tradition since 1985 that recognizes Wood-Mizer portable sawmill owners who have built dream woodworking projects by sawing their own lumber.

The contest is open to any Wood-Mizer portable sawmill or woodworking equipment owner in North America interested in competing for their share of $25,000 in prize credits awarded to first, second, and third place winners in each of ten categories including Homes, Small Homes, Barns, Small Barns, Interior, Exterior, Furniture, Unique & Unusual, For the Good of Others, and People’s Choice. The public was invited to vote online for their favorite projects during the two-month contest to determine the People’s Choice Award winners.

With more than 200 projects entered and tens of thousands of online votes, the 2023 Project Contest was a huge success. “Every year, we continue to be amazed by the creativity and craftsmanship of Wood-Mizer sawmill owners all over the world,” said John Smith, Wood-Mizer CEO. “Congratulations to every sawyer who has accomplished their dream of building a project or business with a Wood-Mizer.”

For the Homes and Major Structures category, Tim Kirk from Montana received 1st place for his 5,000+ square foot multi-purpose workshop. "I needed additional shop and garage space and I love log and timber structures. Over 400 timber members were sawn on my Wood-Mizer LT40 Super Hydraulic sawmill," said Tim.

Blake Loree from Texas received 1st place in the Small Homes and Cabins category for his Windsor Chair studio, equipped with a loft and living space. "I used a Wood-Mizer LT40 sawmill along with an EG200 edger to mill over 20,000 board feet of premium southern yellow pine for this building. Both of these pieces of equipment cut beautifully and saved an enormous amount of money versus buying lumber already cut," said Blake.

Sebastian Lombardo’s “Hideaway Farm Barn” was an astonishing 7,500 square foot project, earning him 1st place in the Large Barns and Garages category. “I enjoy my Wood-Mizer LT35 Hydraulic sawmill as I love to cut wood. With the hydraulic controls and a 12’ bed extension, I can run the mill by myself and cut huge logs. I used the mill for the barn project and cut hundreds of logs, the logs that I milled came from developed land of new home construction sites. These logs are typically chipped up and used in a power plant, firewood, or for mulch. I put them to better use,” said Sebastian.

“I purchased my first mill last year, an LT15WIDE with auto feed and the trailer package. All the features and functionality have been great. Even for the hobbyist, I can’t imagine milling all this wood without the auto feed, well worth the money,” said 1st place winner in the Small Barns and Sheds category, Doug Palladino from Oregon.

The cedar table and bench set were created by Grant Boiser from Florida, 1st place winner in the Furniture category. “All of the wood used for this project was cut using my LT40 sawmill. I cut the logs, resawed the boards, cut the stumps to height, and then cut the benches to their final height once assembled,” said Grant.

Saving more than $10,000 on his farmhouse renovation, Cory Hill from Pennsylvania took home 1st place in the Interior Projects category. “I used my Wood-Mizer LT40 Super Hydraulic to cut the wood for this project. The Wood-Mizer allowed me to cut the wood to my desired specs for making the flooring, trim, and paneling,” said Cory.

Wood-Mizer LT40 portable sawmill owner Hugo Chartier from British Columbia was awarded 1st place in the Exterior Projects category for his round house project. "It is a 30-foot diameter round platform with reciprocal log gazebo in the middle of an old growth forest. This place is out of this world! I had my wedding in the structure,” said Hugo.

“It started as a conversation on a first date. It ended with a unique yoga studio and a marriage proposal. We built a timber framed 192-square-foot yoga studio from locally sourced standing dead timber. All of the trees for the project came from a local forestry project 25 minutes away. All of the timbers as well as the floors were burnt and brushed for looks and function. Jillayne learned to operate the LT15 sawmill completely on her own. She also learned how to cut joinery and raise a timber frame. I learned a lot more about yoga,” said Parker Dunbar from Colorado and 1st place winner in the For the Good of Others category.

The Trinity Knot Chapel by Wood-Mizer LT40 portable sawmill owner Jon Scott from New York, won 1st place in the Unique and Unusual category. “The Trinity Knot Chapel wouldn't exist were it not for the Wood-Mizer. I milled the lumber for my friends and farm owners Bill Miskimen and his wife, Amy Finnegan. The structure incorporates exposed cherry post-and-beam construction, plus antique glass windows reclaimed from the Tiffany Estate in Greenwich, CT and a brass bell, cast in 1820 in Troy, NY and obtained from a bell restorer in Michigan,” said Jon.

Receiving more than 1,000 public votes online for his outdoor shower project, John McKay from Pennsylvania won 1st place in the People’s Choice category. “For years I would take my lumber to a nearby mill to be sawn for my building projects. With grown children, I had the expendable income to buy a mill. I wish I'd done it twenty years sooner,” said John.

All projects from the 2023 contest are showcased in the Wood-Mizer Project Gallery online at project.woodmizer.ca.

2023 My Wood-Mizer Project Contest Winners

Homes & Major Structures | Small Homes & Cabins |

First Place: Tim Kirk– Red Lodge, Montana | First Place: Blake Loree – Waco, Texas |

Second Place: Andrew Ross – New Brunswick, Canada | Second Place: Dennis Raymond – Glen Spey, New York |

Third Place Tie: Derek Byers – Camano, Wyoming | Third Place: Jan Kronke – Eugene, Oregon |

Third Place Tie: Jason Hooft – Prince George, British Columbia |

|

Large Barns & Garages | Small Barns & Sheds |

First Place: Sebastian Lombardo – Leonard, Michigan | First Place: Doug Palladino – Silverton, Oregon |

Second Place: Andrew Worcester – East Wallingford, Vermont | Second Place: Russell Jacobs – York, Pennsylvania |

Third Place: Benjamin Roark – Cold Brook, New York | Third Place Tie: Joseph Scolastico – Duxbury, Massachusetts |

| Third Place Tie: Toni Toth – Chugiak, Alaska |

Interior Projects | Exterior Projects |

First Place: Cory Hill – Lehighton, Pennsylvania | First Place: Hugo Chartier – Ucluelet, British Columbia |

Second Place: Stephen Antony – Hackensack, Minnesota | Second Place: Zach Beyer – Arnold, Missouri |

Third Place: Jeffrey Grimm – Fremont, Indiana | Third Place: Mike Ciesiensky – Hammond, Louisiana |

For the Good of Others | Unique & Unusual |

First Place: Parker Dunbar – Salida, Colorado | First Place: Jon Scott – Briarcliff Manor, New York |

Second Place: James Brink – Anderson, California | Second Place: Joshua Swan – Washburn, Wisconsin |

Third Place Tie: Beau Servo – Kalispell, Montana | Third Place: Peter Campbell – Ridgefield, Connecticut |

Third Place Tie: Keith Kelley – Newport, Maine |

|

People’s Choice Award | Furniture |

John McKay – Lackawaxen, Pennsylvania | Grant Boiser– Alachua, Florida |

Cory Loveland – Elk City, Idaho | David Hillesland – Mehama, Oregon |

James Surles – Bronson, Florida | Bob Brown – Logansport, Indiana |

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a global-leading sawmill and woodworking equipment manufacturer with a strong legacy from its innovative sawmilling products. From Forest to Final Form®, Wood-Mizer offers an extensive line of equipment including portable and industrial sawmills, resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, sawmill blades, and blade maintenance equipment. For more than 40 years, Wood-Mizer remains committed to serving sawmilling and woodworking hobbyists and professionals all over the world throughout an established and growing distribution network. Visit woodmizer.com for more information.

METAIRIE, LA – Connecting. Exploring. Discovering. That was the agenda for the 37th Forest Products Machinery & Equipment EXPO from August 23-25, 2023, at the Music City Center in Nashville, and early feedback shows exhibitors and attendees alike were able to successfully check off all three items on that agenda.

After six shows in Atlanta dating back to 2011, the Southern Forest Products Association (SFPA), which hosts the biennial event, moved the show with exhibitors and attendees applauding the new host city and venue.

EXPO 2023 exhibit space actually sold out three different times before SFPA had to close booth sales because all available space was claimed. The final floorplan topped out at 217 exhibiting companies – a record number of exhibitors since 2007 – spread over 58,337 square feet of machinery, innovation, and solutions to meet with more than 1,200 attendees.

“The move to Nashville exceeded all expectations," said Eric Gee, SFPA’s executive director. "It was great to see so many members of the forest products industry in attendance to be a part of this historic moment. I’m extremely proud of the exhibiting companies that helped transform the exhibit hall into a first-rate networking space.”

Since 1950, Forest Products EXPO has provided a place for both hardwood and softwood sawmillers to gather, celebrate new technology, network, and learn about the industry’s latest machinery and equipment.

The three-day tradeshow provided attendees with solutions for nearly every stage of manufacturing. From raw material handling to crane operations; metal detection and scanning technologies; log optimization, drying, grading, sorting, packaging, and distribution.

Onsite Activities

SFPA announced the 2022 John Edgar Rhodes Sawmill Safety Excellence Awards during the Sawmill & Safety Awards Breakfast on Thursday, August 24. This is the second year in a row there are seven mills receiving 2022 Sawmill Safety Awards with zero incidents among them. Click here to learn more about the 2022 recipients.

New this year included a welcome reception and The Lumber Yard, which expanded EXPO’s networking center with an outdoor-live feel that included wood picnic tables and activities.

Attendees also had the option to attend Productivity & Efficiency: A Conference by Timber Processing co-located at the Forest Products EXPO on Thursday, August 24.

“With nearly one-third of U.S. Forested Land, Southern States produce more than $100 billion in forest products,” said Alaina Hanson CPA, SFPA’s director of administration. “Nashville was the perfect choice because it’s within easy driving distance for both Southern Pine sawmills and hardwood sawmills. The surrounding areas, including the Eastern U.S. hardwood community, represent 42% of all lumber manufactured in the United States.”

Stay tuned to SFPAexpo.com for future host city and dates to be announced in the coming weeks. Booth sales for the 38th Forest Products Machinery & Equipment EXPO are scheduled to open in June 2024, while registration is scheduled to open in March 2025.

EXPO 2023 By the Numbers

These are preliminary numbers. SFPA will announce final numbers in the coming weeks after a thorough audit.

- Attendees

- 1,342 registered

- 1,228 confirmed

- 91.5% attendance rate

- Exhibitors

- 217 exhibiting companies

- 1,017 exhibitor personnel

- 58,337 square feet of displays

- International Component

- 319 international attendees

- 21 countries represented

- Attendee Demographics (pre-audit)

- Key Category

- 71% - Manufacturing/Processing

- 15% - Non-Exhibiting: Equipment Manufacturing/Dealer/Distributor

- 13% - Forestry/Logging/Harvesting

- 1% - Academia/Student

- Job Title

- 32% - Company Officer/Owner

- 21% - Marketing/Sales

- 15% - Engineering/Operations

- 10% - General manager

- 7% - Purchasing/Maintenance

- 6% - Production manager

- 5% - Superintendent/Foreman

- 2% - Research and development

- 2% - Student

- 1% - Professor

- 1% - Safety team leader

- Key Category

Wood-Mizer introduces the PC100 Upcut Saw for cross cutting boards from 1" x 13" up to 4" x 9" with convenience, versatility, and precision. The PC100 joins the Wood-Mizer product line that includes an unmatched selection of products for the sawmill, woodworking, and pallet manufacturing industries.

Available in left or right-side blade options, the PC100 Upcut Saw features convenient center material loading for longer material with a uniquely designed segmented blade guard. When the two-hand no-tie down cutting cycle is activated, the upper blade guard automatically lowers and covers the front and sides of the blade during the cutting cycle. Comparable machines with a mounted blade guard only allow material loading from the left or right side which makes processing longer material more difficult and time consuming. Additional features include up to 20 cut cycles per minute, 1-phase or 3-phase electric power, optional infeed/outfeed tables, optional gang stop, and more.

“Wood-Mizer is dedicated to providing the best-in-class equipment for a variety of timber and wood processing needs throughout the world,” said Russell Fite, Wood-Mizer North America Sales Director. “Sawmill, woodworking, and pallet operations will all appreciate the well-designed features of the PC100 including center material loading for ease of operation, left or right-side blade options for versatility, and up to 20 cut cycles per minutes for production efficiency.”

Built in the USA, the PC100 Upcut Saw is now available to order in North America. For more information, visit www.woodmizer.ca or contact your local Wood-Mizer representative.

About Wood-Mizer

Since 1982, Wood-Mizer has earned the reputation as a world-leading wood processing equipment manufacturer with a strong legacy from its innovative sawmilling products. From forest to final form, Wood-Mizer offers an extensive line of equipment including narrowband portable and industrial sawmills, wideband sawmilling equipment, band resaws, board edgers, wood kilns, planer/moulders, firewood processing equipment, pallet recycling equipment, material handling equipment, sawmill blades, and blade maintenance equipment for woodworking and forestry hobbyists and professionals all over the world. Visit woodmizer.ca for more information.

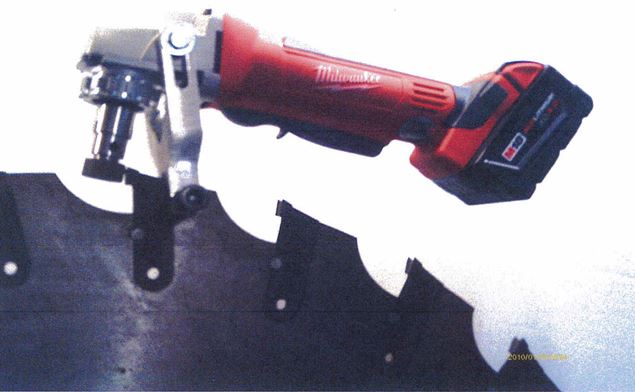

Jones Saw Tools has now added another innovative product to their quality line of saw sharpening tools. Jones Model SX33C Cordless Slasher Saw Sharpener provides firewood processors and mills without electric or air power the ability to sharpen their ITCO saws right on the saw, right on the job site.

Milwaukee M18 motor is compatible with customer's current M18 charging system or charger and batteries can be purchased separately.

Easy to mount. Easy to use.

For more information, contact:

Randy Jones at Jones Saw Tools 812-789-3448

McDonough Manufacturing is excited to welcome BID Canada Ltd. into the McDonough group of companies. This acquisition partners two of New Brunswick’s premiere manufacturing teams and facilities, combining them with our flagship location in Eau Claire, Wisconsin, and allows McDonough to increase production capacity, human resources, and product offerings.

McDonough Manufacturing was founded in Eau Claire, Wisconsin in 1888, expanding operations to Mactaquac, New Brunswick, in 2017. Increasing demand of our machinery has necessitated a further expansion to increase capacity and meet changing market needs.

BID Canada Ltd. has over 50 years of experience in the design and manufacturing of bulk material handling systems, making it one of North America’s leaders in the industry. Within close proximity to the Trans-Canada Highway and various seaports, BID has been a sought-after manufacturer in the coal, cement, potash, nickel, biomass and pulp and paper industries.

This acquisition is part of McDonough’s business strategy to continue to offer the best machinery on the market, while employing teams of experts to service our customers. BID Canada will continue to operate in their facility in Woodstock, New Brunswick, retaining existing team members under the McDonough umbrella. The BID Canada location will remain focused on their existing customers and projects, while contributing to the production of McDonough sawmill machinery. The experience of the McDonough sales and marketing teams will allow us to further expand BID Canada’s horizons across North America.

This is an exciting chapter in the 135-year history of McDonough Manufacturing, and we are grateful for the support of our many customers, vendors and supporters. We are confident that this expansion will only serve to increase our capabilities and we look forward to welcoming in our new BID Canada team members.

Go Fast Manufacturing (Go Fast) in partnership with WMEP Manufacturing Solutions (WMEP) is pleased to announce they will be receiving a grant award presented by the Wisconsin Economic Development Corporation (WEDC) recognizing the first completed project eligible from WEDC’s Wisconsin Automation Implementation Grant. This event, which includes a brief presentation, plant tours, and lunch, takes place on March 28th from 11 am – 2 pm at Go Fast’s facility at N3752 Drier Road, New London, WI 54961.

WEDC CEO Melissa Hughes, Go Fast’s President Dan Berken, elected officials, and representatives from WMEP Manufacturing Solutions and Wisconsin Center for Manufacturing & Productivity will provide brief remarks on the Wisconsin Automation Grant, and Go Fast’s successful automation selection and implementation project.

The Wisconsin Automation Grant is designed to lower the risk of companies’ automation implementation by providing project selection and implementation assistance through WMEP’s Automation Advisor™, and financial support from the WEDC. This program helps support companies’ implementation of technology that mitigates the effects of long-term worker shortages, while increasing productivity and innovation capabilities leading to increased competitiveness and growth opportunities for Wisconsin manufacturers.

Go Fast Manufacturing is a rapidly growing “one-stop” pallet and sawmill equipment company that offers a catalogue of machinery that includes conveyors, green-chains, trim saws, resaws, dedusters, chopsaws, board stackers, and notcher machines. Go Fast focuses on innovation and always strives to build machine designs that allow their customers to achieve new levels of productivity and profitability.

For more information, Jenny Shipper [email protected], 920-851-9941, at A-mazing events, or Duane Brown at Go Fast, [email protected].

The 85th Annual Oregon Logging Conference boasted more registered attendees and exhibitors this year and did not disappoint all who attended. The inclement weather did cause cancellation of elementary school tours and prevented some of the students from attending the Future Forestry Workers Career Day but did not dampen the spirits of all those who came out to the Lane Event Center and Fairgrounds in Eugene, OR.

Overall, pre-registered attendance was up 18% and exhibitor participation was up 17% over last year. As the weather improved during the OLC, so did attendance, especially on the final day of the Conference, which is Family Day, and also open to the public with no admission charge.

85th Annual Oregon Logging Conference President Craig Olson said, “Our theme ‘Green Trees Matter. Healthy Forests = Healthy Future’ reflected the importance of our industry. Our keynote speaker Travis Joseph and the many panels and seminars all touched on topics impacting our industry, the importance of forests, and the products that are provided.”

Conference Manager Rikki Wellman said registration was up this year and there were more displays including several first-time exhibitors. “The icy weather caused only minor challenges for those planning to attend the 85th OLC,” and she added, “many still came out to review the latest technology in logging equipment”.

2023 Keynote speaker – Travis Joseph

Keynote speaker Travis Joseph said he and his organization need help telling the truth about logging and the wood products industry.

He called it a big lie, the concept of logger versus environmentalist, with loggers destroying the forest and only it for the money and environmentalists protecting the forests and saving the planet. Not only a lie, Joseph said, but a perception with “dangerous implications on communities, forests, the environment, and the future.”

“You are the people who provide all the products, materials, and services we all depend on every day of our lives,” Joseph told the gathering, and added, “We have to stop letting ourselves be bullied about environmentalism by a bunch of hypocrites and celebrities.”

He asked everyone in the room to get involved. “We’re in this together,” Joseph said, “no one can be sitting on the sidelines right now. Let’s keep fighting, let’s keep working together, let’s not give up, we can change this,” he said.

Future Forestry Workers Career Day

Nearly 300 high school students from 14 Oregon schools attended the 5th Annual Future Forestry Workers Career Day. A higher number of students and schools had signed up to attend but were forced to cancel due to bad weather.

The students interacted with industry professionals and learned about job opportunities and careers in sawmills, reforestation, truck driving, equipment operation, welding, and diesel mechanics.

Students also had an opportunity to use virtual timber harvesting technology, provided by the Oregon State University Forestry Department.

February 23, 2024 is the date planned for the 6th Annual Future Forestry Workers Career Day, to take place at the livestock arena on the Lane County Fairgrounds in Eugene.

A high school logging and forestry skills competition is included as part of the Future Forestry Workers Career Day which included students from five high school forestry clubs compete in activities including cable splicing, choker setting, crosscut and single buck sawing, compass and pacing, tool identification, log scaling, and axe throwing. This skills competition has been part of the Oregon Logging Conference for more than 25 years.

Philomath High School took 1st place, 2nd place was Sweet home High School, 3rd place was La Pine High School, and 4th place was Scio High School.

Desserts for Dreams Luncheon Raises Money for Wildland Firefighter Foundation

More than $15,000 was raised at this event for the Wildland Firefighter Foundation, which provides support for families who have lost loved ones fighting wildland fires.

The Foundation was established after the loss of 14 firefighters in 1994 at Storm King Mountain in the South Canyon Fire in Colorado. Founder Vicki Minor and several family members of those fallen firefighters attended the luncheon. Minor told the gathering “These families helped create this Foundation, and it has helped these families learn how to live again.”

Oregon Logging Conference Foundation Auction

$27,000 was raised during the Thursday and Friday auction at the Oregon Logging Conference. This money will be deposited in the Oregon Logging Conference Foundation scholarship program. OLCF expressed its appreciation to all donors, winning bidders, auctioneer Jaime Yraguen of Basco Logging, and Will Garrett and other volunteers from Radiator Supply House.

Seminars and Panel Discussions

Topics of current interest were discussed at the 85th Annual Oregon Logging Conference, while many of those attending earned Professional Logger credits to stay certified and up to date on several issues. Topics addressed included:

- Engaging the Next Generation Workforce

- Succession Planning for Logging Companies

- The Connected Forest and New Technology Around the World

- Your voice, Your Vote Counts and speakers Christine Drazan and Oregon Representative Shelly Boshart Davis

- Electrification of Equipment

- Business Advice for Today’s Logging Companies

- Oregon and Washington Forest Practices Acts

“The Oregon Logging Conference was packed with unique opportunities for forestry and natural resource professionals to network and learn more about their trades,” said OLC Manager Wellman.

Log Loader Competition

Just like last year and previous years, the winners of the Oregon Logging Conference Log Loader Competition are familiar names.

First place was Bryan Chipps of Green Diamond Resource Company in Humboldt County, CA, with a time of 4:05:00. Chipps was the third-place winner in 2022. Second place went the Zane Bryant of Bryant Logging in Beaver Creek, OR, with a time of 4:15:37. Bryant was last year’s first place winner. Third place this year was Ross Cribbs of Black Rock Timber, with a time of 4:48:15.

This popular outdoor event tests the skills of log loader operators, as they demonstrate speed, skill, and efficiency. Operating a Link-Belt log loader, contestants have seven minutes to stack log blocks end-to-end, matching numbers or colors on predetermined marks on the ground.

Event sponsors are Triad Machinery and Link-Belt, wood chunks were provided by Cascade Timber Consulting and Burke Logging.

Guess the Net Scale – 2 Winners This Year

Along with the traditional guess the net scale load of logs, this year there was a load of chip and saw logs testing guesser’s scaling abilities. The two winners are:

Jay Messerle of Messerle & Sons Logging in Coos Bay was the winner with his guess of 2,920 feet for the load of chip and saw logs. The actual scale was 2,910 feet. Thank you to Jacob Steensen and Southport Lumber, Sierra Pacific Industries, and Terry and Louis Mann, L & L Inc.

Mike Edwards of the road building engineering department at Lone Rock Timber has the closest guess for the net scale of the chip and saw logs. The second load of logs had an actual scale of 8,040 feet and Edwards guess was 8,050 feet. Thank you to Derek Lee and Swanson Brothers and Leonard Maser Trucking.

Messerle and Edwards each received a $250 Cabela's gift card.

Family Day

There was a good turnout on the final day of OLC, with many taking advantage of Family Day activities and enjoying outdoor and indoor displays, including state-of-the-art logging, construction, and trucking machinery. The final day of the Oregon Logging Conference, Family Day activities included bird house building, live wildlife, face painting and educational displays.

Oregon Women in Timber Dinner/Auction

The Talk About Trees dinner/auction was a huge success with sellout crowd of 480 people in attendance. The dinner/auction’s gross proceeds of over $150,000 will help support OWIT’s Talk About Trees forest education program, which is offered free to pre-Kindergarten through 8th grade students.

86th Annual Oregon Logging Conference

The dates are set for the 86th Annual Oregon Logging Conference. Plan to attend the OLC February 22 - 24, 2024 at the Lane Event Center and Fairgrounds in Eugene, OR.

For more information, contact Rikki Wellman, OLC Manager, (541) 954-2477 or Mary Bullwinkel, Media/Communications Coordinator – (707) 601-6533.

Cooper Machine Company, a long-established manufacturer of quality sawmill equipment located in Wadley, Georgia, announces that it is partnering with the sawmill machine manufacturer EWD Sagetechnik, of Altötting, Germany, as of February 2023.

We at Cooper Machine have been offering our customers located in the US, Canada, and other countries, wood processing equipment for sawmill, pallet, and post and pole mills since 1965. This equipment has set new standards in the industry for quality, efficiency, and productivity. All Cooper Machine equipment is built with our customers in mind to minimize labor and to get the most out of each log. Our company, now in its third generation of successful management, covers all services from technical development, to commissioning, to sawmill staff training on our machines. Cooper Machine’s focus is always on customer success.

Since 1862, the premier European innovative company EWD, with 250 employees in Germany, is one of the world’s leading companies in sawmill plant construction. Quality awareness, reliability, and customer orientation are among the most important values of the company and represent an extremely positive success factor.

The partnership with EWD Sagetechnik, allows Cooper Machine to expand its portfolio and take advantage of the opportunity to offer an expanded range of sawmill equipment to further serve our customers’ needs.

“In the future, with labor getting more expensive and harder to find, we want to offer our customers fully automated sawmills. With the same shared beliefs, we believe we have found the ideal partner in EWD Sagetechnik” explains Frances Cooper, CEO of Cooper Machine.

Working with EWD will offer many advantages for Cooper Machine customers since we will be able to offer their wide array of well-designed, German engineered sawmill equipment, along with service and parts located here in the US. Cooper Machine has committed to providing successful customer service on all EWD equipment it sells and will stock the parts needed to back the service. We at Cooper Machine are excited to be able to offer this new world of opportunities to our North American customers.

The primary objective of both companies is to offer customers the best and most efficient sawmill solutions to promote long-term customer loyalty. This can only be achieved with trust, good teamwork, and positive results for our customers.

For information on both Cooper Machine and EWD offerings, please give Cooper Machine a call at 478-252-5885.

Forestry Systems introduces the MILL BOSS, specifically engineered to provide small to medium sized sawmills with a simple, affordable, all-in-one solution for handheld and tablet. The MILL BOSS easily handles all of your operation's tracking - from logs to lumber - ensuring total control of log scaling, log AND lumber inventory, vendor settlements, sawmill consumption, log sales, lumber tally and lumber shipments.

Designed to be user friendly, the MILL BOSS starts working right out of the box, and utilizes many of the innovative routines from Forestry Systems’ most popular and widely used programs. The MILL BOSS specifically features routines from the Log Scaler and Block Tally – with the addition of improved log inventory, inventory search functionality, integrated consumption updates, easy data backup for security and sharing between multiple devices.

The MILL BOSS makes the latest log and lumber inventory and sales management technology available to every size operation. For complete details on the Mill Boss and other software and hardware solutions, contact Forestry Systems, Inc. by calling 800-868-2559 or go to www.ForestrySystems.com.

Opticom Technologies, a leader in industrial video monitoring solutions, is celebrating 50 years in business. The company, founded in 1973, has evolved to continue offering innovative products as video monitoring technology has advanced.

“It’s unique for a video monitoring company to have 50 years of history under its belt,” said Opticom Global Sales Manager Heidi Schmidt. “We’re honored to continue serving our industrial and commercial customers with the latest advances in video technology.”

Opticom was founded by “Richard” David Boyd, a proponent of CCTV monitoring long before adoption ramped up after 9/11 and the security concerns the terrorist attacks brought forward. Boyd passed away in 2021, but his legacy continues.

With its rugged products, designed to withstand harsh environments, Opticom Tech best serves commercial and industrial companies like sawmills, mines, food processing plants, and other facilities with dust, vibration, moisture, and other elements not generally accommodating to video equipment.

“Our product development centers around designing products throughout the entire video monitoring system — cameras, mounts, monitors, connectors, and more — that can survive in tough environments,” said Schmidt. “Our customers can’t afford to stop production to troubleshoot or replace a video camera, so we build products that last; a fact reflective in our 50-year history.”

Products of note developed by Opticom include its CC02 rugged industrial analog and TVI cameras, CC03 explosion-proof cameras, CC04 high-definition IP networking cameras, and VM-1 vibration shock mounts.

Opticom will be celebrating its 50th year throughout 2023 with customer acknowledgements, giveaways, and other announcements.

About Opticom Tech

Founded in 1973, Opticom Technologies provides integrated video monitoring solutions for industrial applications, including sawmills, mines, food processing facilities, and more. Built to withstand harsh environments, Opticom’s rugged cameras and equipment stand the test of time. For more information, visit www.opticomtech.com.

###

Cooper Machine Company, Inc. of Wadley, Georgia, would like to announce that it has promoted Daniel Sherrod to Vice President of Manufacturing. We would also like to announce that in January 2023 Robert Cooper plans to hand ownership of the business to his daughter and CEO Frances Cooper, and to Daniel Sherrod, who began at Cooper Machine in 1996 and who has been in charge of the shop floor for many years. Robert has no plans to retire. Instead, he will continue working with the company indefinitely, both from his office at the business and his home office located in his workshop, where he enjoys making barrel and other wood furniture. He will also still be on the road visiting customers just as he has been doing. Although Robert hopes to spend more time in his workshop and less time at the business, he appreciates his customers, many of whom he has worked with for decades, and wants them to know that they can still count on him and the Cooper Machine team to take care of their equipment and service needs.

.gif)