BLOW THE WHISTLE ON MISCUT LUMBER

TRACK RECORD ON SAW DEVIATION

Interest in tracking saw deviation has continued to grow in

the forest products industry as limited resources,

expensive stumpage, and keen competition have driven

mills to look for ways to increase yield and bring more

dollars to the bottom line.

Tracking devices or detectors can sense when a saw is deviating

from the set tolerances and warn the operator, who in tum can slow the

feed speed to avoid miscutting lumber. It’s a simple concept, but the

benefits of such monitors can be quite substantial.

There are plenty of problems that can cause a saw to deviate and a

number of variables have to be evaluated before pinpointing the cause

of mis-cut lumber once the monitor indicates a problem. There could be

a problem in the initial setup of the mill or the sharpness of the saw

itself, but generally; it’s caused by wood characteristics and varying

densities of the wood being cut.

Saw deviation detectors provide real-time feedback of the exact

position of the blade relative to the expected position. Any deflection

of the blade, whether caused by too high a feed speed, knots, frozen

lumber, dull or damaged blade, trash between the blade and guide

block, or simple guide wear will instantly be detected by the monitor

allowing the operator to correct the situation before lumber is mis-cut or

the saw is damaged. Equally important, by monitoring the blade

position and ruling out blade deviation as the source of mis-cut lumber,

it becomes much easier to effectively zero in on other issues, such as

track misalignment or head blocks out of adjustment, that might be

causing production problems.

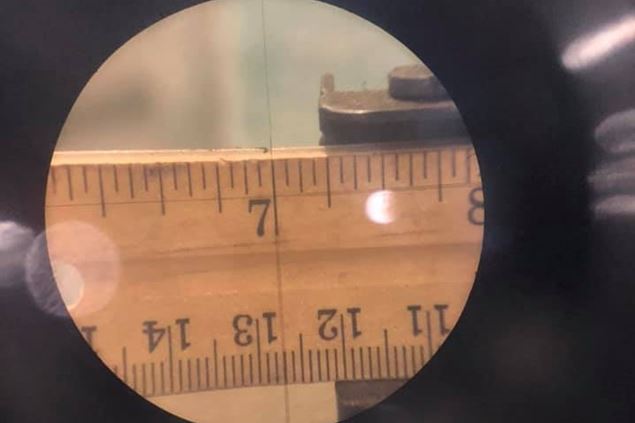

All deviation detectors include a sensor that is placed next to the

bandsaw guide. These sensors actually “feel” where the saw is running

in the cut.

The advantage of real-time information is largely what makes the

increased production possible. With a real-time look at what the blade

is doing, operators can actually see night away if they’ ve cut irregular

lumber, versus finding out when they measure the lumber later on.

DETECTOR DETAILS

Our monitor, which can measure deviations of only a few

thousandths of an inch, uses a proximity sensor, a controller display

unit, and a data cable that connects the two together, to indicate

deviation and sometimes vibration when it actually occurs in the saw.

The “real-time” aspect of the process discourages unplanned downtime.

You don’t have to wait until you get downstream and measure the

lumber to see you have a problem. We can see it while it’s happening-

that’s the real-time aspect of the process.

CONSIDERING A MONITOR?

The monitors can serve in a teaching capacity for first-time

operators. If you've got a new guy in the sawyers cab, it helps him

know how much wood he can push through, and it helps him learn

tolerances. It’s kind of like a speedometer in that the deviator becomes

a good way to gauge how fast you can go and stay within tolerances.

The Sawblade Deviation Detector provides real time feedback from

the proximity sensors, with a visual display that indicates varying

degrees of deflection. The display box is set in the operator’s line of

sight, and contains a series of light bulbs. Green lights indicate a safe

rang, yellow lights warn of deviation out of good operating range, and

red lights indicate deviation beyond acceptable tolerances.

Many industry experts say monitors are tools that give operators and

filer’s insight on saw behavior as well as assuring the correct operation

of the equipment. Every operation, even the most sophisticated sawmill

equipment with the very best in people, as the day goes on, will produce

less than the best lumber.

The payback period is relatively quick. The SD40 model] often has

a payback in little more than 60 days.

A system of lights on the SD-40 display box indicates the saw’s

behavior, a safe operating range is reflected by three green lights in the

center of the display, a slight deviation is reflected by two yellow lights.

which may also indicate the blade is getting dull; red lights and the

sound of an alarm to warn the operator of an unsafe deviation. It lets

you know exactly how fast you can travel through the cut without

“getting stopped” for speeding. On the other hand if you’ve been

traveling “45 and the conditions are such that you could have been

traveling “55”, the deviator lets you know that you are well within

limits, go ahead —go faster!

With only 2+ hours installation time, the Sawblade Deviation

Detector can be purchased for approximately $2,750. The Model SD-

40 comes complete with controller/display module, sensor unit, and

cabling and operates from a standard 110V outlet. It offers an

adjustable setting for sensitivity and allows remote centering of signal

for display.

We are selling one of the lower-priced units on the market. It is our

belief that the maximum benefit is obtained from Deviation Detection

units when they are rugged, simple to install, intuitive to operate, and

inexpensive enough to use on every saw in the mill.

The Deviation Detector can help sort out problems with guide wear

or set works performance. It can help determine proper feed speeds and

aid in calculating the optimum time between blade sharpening. Most

importantly, the Deviation Detector allows the sawyer to push his

equipment to the limit in pursuit of maximum production with full

confidence that he’s not exceeding the capability of the blade.

574-370-5050

AUTOMATION & PROCESS CONTROL

P.O. BOX 3 SHIPSHEWANA, IN 46565